Expert solutions for mechanical engineering industry support to meet your requirements.

Expert solutions for mechanical engineering industry support to meet your requirements.

Blog Article

Leading Tips for Effective Electrical System Troubleshooting

Troubleshooting electrical systems requires a methodical strategy, based in a detailed understanding of electrical principles and security procedures. The subtleties of reliable repairing prolong past simple technical knowledge; comprehending just how to document findings and prioritize security can considerably influence outcomes.

Understand the Basics

Recognizing the essentials of electric systems is crucial for reliable troubleshooting, as a solid structure allows service technicians to identify and fix problems more effectively. A comprehensive grasp of electrical concepts, such as voltage, present, resistance, and power, is critical in determining the origin of problems. Voltage is the electric potential difference that drives current through a circuit, while resistance opposes the flow of present, affecting the total performance of the system.

Familiarity with circuit elements, consisting of resistors, capacitors, diodes, and changes, is also paramount. Each component plays a distinct duty in circuit behavior and can impact performance when malfunctioning. In addition, recognizing collection and identical circuit arrangements is important, as these arrangements influence the circulation of voltage and existing within the system.

Specialists have to be conscious of possible dangers, such as shock and short circuits, to execute secure troubleshooting techniques. By grasping these fundamental concepts, specialists improve their ability to perform efficient diagnostics and repair services, ultimately leading to enhanced efficiency and dependability of electric systems (electrical system troubleshooting).

Gather Necessary Devices

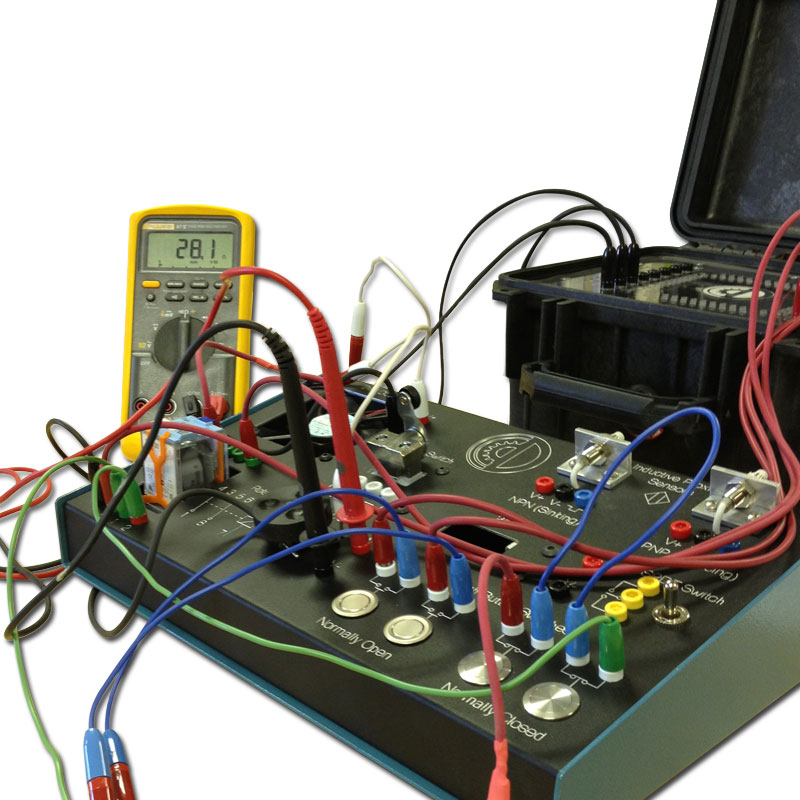

Reliable troubleshooting of electrical systems needs the ideal set of tools to identify and settle concerns properly. A fully equipped specialist can considerably enhance efficiency and effectiveness in determining troubles. Important devices include a multimeter, which measures voltage, current, and resistance, enabling precise examinations of electric components. Secure meters are additionally useful for measuring present without separating the circuit, guaranteeing safety and benefit.

In addition, shielded hand tools such as screwdrivers, pliers, and cord pole dancers are essential for securely controling electric links. It is additionally recommended to have a circuit tester handy to verify the presence of voltage in outlets and cables. For more complex systems, a thermal imaging cam can help find overheating elements, showing possible failings.

Comply With a Methodical Strategy

Having gathered the proper devices, the following step in fixing electric systems is to adhere to an organized strategy. A systematic approach makes sure that professionals can determine mistakes successfully and accurately, lessening downtime and avoiding unnecessary repair services.

Begin by evaluating the system's schematic layouts and requirements. This entails checking each element systematically, starting from the power resource and working towards the load.

Utilize testing tools, such as multimeters and oscilloscopes, to gather unbiased data concerning voltage, current, and resistance at different points within the system. This empirical proof will certainly assist your troubleshooting initiatives and aid to validate or eliminate prospective sources of failing.

Additionally, consider environmental aspects that might affect the system's efficiency, such as temperature changes or dampness access. A comprehensive examination of circuitry, links, and elements will ensure that all opportunities are made up.

Record Your Findings

Extensive documents is essential in the troubleshooting process of electrical systems. Accurate records improve the performance of identifying reoccuring problems and promote communication among employee. Each finding ought to be meticulously noted, consisting of signs and symptoms observed, tests conducted, and the end results of those tests. electrical system troubleshooting. This practice not only help in recognizing the origin of the problem but additionally works as a reference for future repairing efforts.

In addition, preserving a log of parts replaced or repair work carried out is important. This details sustains inventory monitoring and can assist evaluate the longevity and integrity of particular components.

Ultimately, the documentation procedure ought to be comprehensive yet succinct, making it possible for easy access and review - electrical system troubleshooting. By focusing on thorough documents, specialists can produce a useful data base that not only help in current troubleshooting but likewise equips future upkeep initiatives, consequently enhancing total system dependability

Prioritize Precaution

Identifying the intrinsic threats linked with electrical systems is crucial for guaranteeing safety and security during troubleshooting. Electric shock, burns, and tools damages are just a few of the potential risks that specialists encounter. Focusing on precaution is not just a legal commitment but additionally a moral necessary that safeguards both the technician and the surrounding electrical system troubleshooting setting.

Prior to starting any kind of troubleshooting task, service technicians need to wear suitable personal safety equipment (PPE), including protected gloves, security glasses, and flame-resistant clothes. Guaranteeing that the workplace is dry and without mess can dramatically lower the risk of mishaps. Furthermore, it is vital to de-energize circuits before starting any job, verifying that they are not live via the usage of a multimeter or voltage tester.

Establishing clear communication procedures with staff member is also important; this guarantees that every person knows potential dangers and the status of the electric system being functioned on. Having an emergency situation feedback plan in area can prove very useful in the occasion of an event. By prioritizing security measures, specialists can properly mitigate threats and foster a more secure work environment.

Conclusion

Effective electrical system fixing counts on a comprehensive understanding of fundamental concepts and a systematic method. By collecting vital tools, sticking to systematic analysis techniques, and diligently recording findings, the repairing process ends up being much more effective and dependable. Prioritizing safety steps makes sure the well-being of people involved and the honesty of the electric system. Executing these methods will enhance the repairing experience, resulting in quicker resolutions and improved functional efficiency in electric systems.

Report this page